Secondary Suspension Shims

Shimming secondary suspension elements in a railway vehicle is of paramount importance for a number of reasons:

- Derailment Safety: Shimming directly affects the alignment of the wheel-rail interface, which is critical for safe train operation. Incorrect or uneven shimming can cause an imbalance in the load distribution on wheels, leading to increased lateral forces and the potential for wheel climb and derailment.

- Axle Balance: Correct shimming is essential to maintain the axle load balance. Uneven axle loads can lead to premature wear and tear of components, reduce the vehicle's stability at higher speeds, and cause poor ride quality. It can also lead to rail deformation and rail breakage, presenting severe safety risks.

- Vehicle Levelling: Shims are used to ensure that the vehicle body is levelled, which is crucial for passenger comfort and safety. Incorrect levelling due to improper shimming could cause tilting, leading to the vehicle moving outside its kinematic envelope and potentially causing collisions with other trains and rail infrastructure.

Shimming secondary suspension elements correctly is a fundamental maintenance activity that helps ensure the safe, efficient, and comfortable operation of rail vehicles. It helps to prevent derailments, maintain axle balance, and provide a levelled vehicle body for optimal passenger comfort and safety. Incorrect shimming can lead to significant risks and should be avoided.

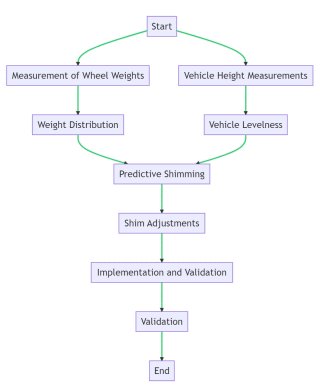

ExcelWraps' predictive method revolutionises the traditional approach of shimming secondary suspension elements by replacing the laborious trial-and-error process with a more data-driven and scientific method.

- Measurement of Wheel Weights: The ExcelWraps solution starts by accurately measuring the load (or weight) on each wheel of the vehicle. This gives a clear picture of how the weight is distributed across the vehicle and highlights any imbalances that may exist.

- Vehicle Height Measurements: Concurrently, the height of the vehicle at various points is also measured. This gives an idea of the vehicle's levelness and its relative position with respect to the track.

- Predictive Shimming: Based on these measurements, ExcelWraps' predictive method calculates the precise amount of shimming required at each secondary suspension element to correct any imbalances and level the vehicle correctly. This is a significant improvement over the traditional trial-and-error approach as it provides a targeted, data-driven process to guide shimming adjustments.

- Implementation and Validation: The suggested shim adjustments are then implemented, and a further round of wheel weight and vehicle height measurements are taken. This allows validation of the adjustments and further fine-tuning if required.